Confirming to IS 4137

FEATURES OF LADLE CRANES :

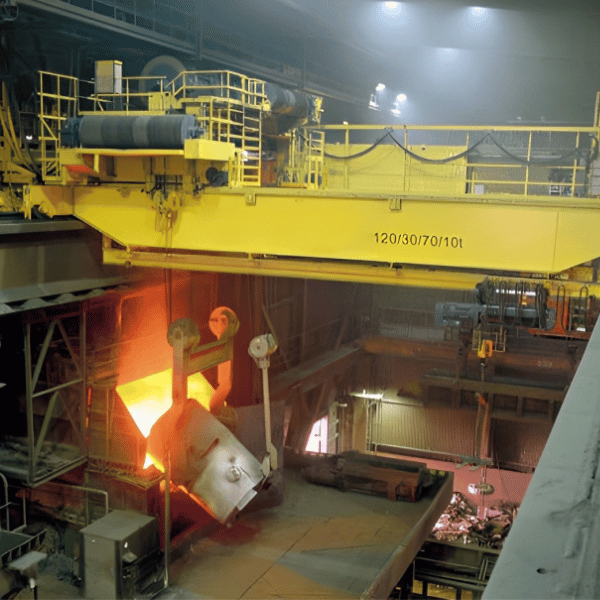

Ladle cranes are designed to be operated efficiently, uninterruptedly and safely in continuous use. The design conforms to the requirements of Relevant IS standards.

Due to a higher risk level, special safety features are designed for the ladle cranes that transport molten metal. The main hoist mechanism includes four independent rope reevings, double service brakes on primary shafts, and backup brake acting on the rope drum. Rope equalizer beams are provided with a dampening unit to slow down equalizer beam tilting in case of wire rope failure. An upper emergency stop limit switch is also used in the main hoist. In addition to this overload protection, the ‘emergency stop’ system bypassed from PLC, derailment supports, main hoist over speed supervision, and end limit switches are automatically standard features of the equipment.

UNIQUE FEATURES:

• State-of-the-art designs confirms to Indian and International Standards.

• Easy to commission, having maximum rigidity with a minimum dead load

• Safe and reliable hoisting and travelling

• Girders are cambered to an account equal to the deflection caused by dead load and half the live load of trolley

• Full length platforms on both sides for ease of maintenance

• Micro speed will be attained through (VFD) Drives

• Steel Core hoist rope having minimum factor of safety of 8

• Safety and better productivity are ensured with advanced automation option

• Safe and substantial production of cranes in compliance with ISO 9001

• Higher efficiency to save power

• All motions are protected with limit switches

VARIANTS:

• Double girders overhead travelling cranes

• Single girder overhead travelling cranes

• Grabbing Cranes

• Ladle Cranes

• Goliath / Semi Goliath Cranes

• Single Girder / Double Girder Under slung cranes

APPLICATION AREAS:

Steel Furnaces, Steel mills, etc.